INTRODUCTION

Whenever a new standard hits the industry manufacturers are usually presented with two choices, either design, develop and manufacture new products or take their existing ones and upgrade them to comply with that standard. Designing, developing and manufacturing a new product is not only time consuming (and in the electronics industry time is everything), it also requires massive amounts of money and so at least in regards to flagship products the second option is usually that which prevails. In late 2022 FSP introduced their Hydro PTM PRO line of power supply units (1200W review here) and since this line proved to be among the very best in the market the obvious choice was to make it ATX 3.0 and PCIe 5.0 compliant and once again today I'll be testing the latest 1200W variant.

FSP Group is one of the global leading power supply manufacturers. Since its establishment in 1993, FSP Group has followed the management conception “service, profession, and innovation” to continuously fulfil its responsibilities as a green energy resolution supplier. With the combination of its leading role in power supply technology and the cultivation of green energy field, FSP Group now provides more competitive quality products and makes itself the most reliable partner for customers, consumers, and suppliers with joint creation of maximized values.

The now upgraded Hydro PTM PRO line of power supply units by FSP currently includes 850/1000/1200W output models all of which are fully modular, compliant with all the latest standards (ATX12V V3.0, PCIe 5.0, EPS12V V2.92 and IEC 62368) and are also 80 Plus Platinum efficiency certified (over 92% electrical efficiency). The 1200W variant sports a single +12VHPWR 600W power cable, single powerful +12V rail (100A) capable of delivering 100% of the units’ total power output (1200W), peak power output of no less than 1338W (although once again according to ATX 3.0 specs peak should now be up to 2.4KW for up to 100ms duration – not something i can check however), 6 PCIe 6+2 connectors, active PFC, advanced stability and voltage regulation (thanks to its LLC full bridge topology with DC-to-DC technology), 100% Japanese capacitors, fan ECO mode with 0dBA function (reduced power consumption and noise at low loads) and interior conformal coating (dust, humidity and stain protection). Finally, the new Hydro PTM PRO power supply units are covered by a 10-year limited warranty and feature numerous electrical protections such as OVP (over-voltage), UVP (under-voltage), SCP (short-circuit), OPP (over-power), OCP (over-current) and OTP (over-temperature).

SPECIFICATIONS AND FEATURES

PACKAGING AND CONTENTS

The box used by FSP has a large product picture at the front surrounded by the main product features, company logo, output and a paper showcasing the ATX 3.0 & PCIe 5.0 feature.

Typically, the power cord type is tagged on the left side of the box.

A drawing at the base of the box is used to point to the number of modular power cables.

Another product picture is placed at the rear next to the features list.

The PSU is placed between two pieces of black foam whereas the modular power cables are placed inside a storage/carrying pouch.

Along with the Hydro PTM PRO 1200W (ATX 3.0) its power cord and modular cables inside the box you'll also find a test adapter, cable straps, 4 mounting screws, 4 side stickers, +12VHPWR correct usage paper, warranty paper, manual and the user guide.

THE HYDRO PTM PRO 1200W (ΑΤΧ 3.0) EXTERIOR

Aside the braided +12VHPWR cable every other modular cable is a low-profile (slim) one.

Measuring 190mm in length, 150mm in width and 86mm in height the new Hydro PTM PRO 1200W is as expected identical to its predecessor.

The 135mm FDB (fluid dynamic bearing) fan is located underneath a grille with the line logo at the center.

Both sides of the enclosure feature replaceable stickers which can be swapped with the bundled ones if they match your taste better.

Turning the unit over we find the sticker with its electrical table on it.

All 14 modular connectors are both tagged and different in shape.

At the rear we find the usual honeycomb perforation along with the eco and power on/off switches and of course the power port.

THE HYDRO PTM PRO 1200W (ΑΤΧ 3.0) INTERIOR

Once again, the 135mm FDB fan used with the Hydro PTM PRO 1200W (ATX 3.0) is manufactured by PROTECHNIC ELECTRIC and can reach a maximum rotational speed of up to 2300RPM to produce up to 115.8 CFM of airflow with 40.8 dBA of noise.

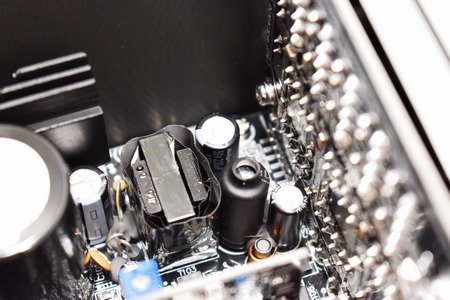

Using an almost wire-free interior was something i really liked with the original Hydro PTM PRO 1200W and of course the same applies here (also let's not forget the special heatsink present for the 12V switching circuit).

This time over FSP has used Rubycon for their primary capacitors which are certified for use up to 105 degrees Celsius.

Secondary capacitors are by Rubycon and Nippon Chemi-Con (these are also certified for use up to 105 degrees Celsius).

TEST BED

TESTING METHODOLOGY

Using a dedicated measurement instrument such as a Chroma or a SunMoon to test power supply units is without doubt the most ideal and accurate way (not to mention the fastest) to do that currently. However, it's certainly not the only way there is and so pretty much anyone can test a power supply unit just by using a test rig. Certainly, limitations do apply and so you can't really push a 1000W power supply to its limits if your system only uses 500W at peak loads and that's why over the years we saved certain hardware components for the purpose of building a dedicated PSU test rig. True it may not be as accurate as the above mentioned solutions but it comes really close and is in fact much closer to real world usage. So as always, we ran several games with maximum graphic options enabled at a resolution of 2560x1600 in order to stress every hardware component and increase the overall power demands of the system. The Passmark BurnIn Test was also used to overstress the components in an effort to provide the most accurate results possible. As a final test we also used the latest OCCT 4.4 software and its dedicated PSU testing suite since it can really bring a power supply to its knees after inside a few minutes.

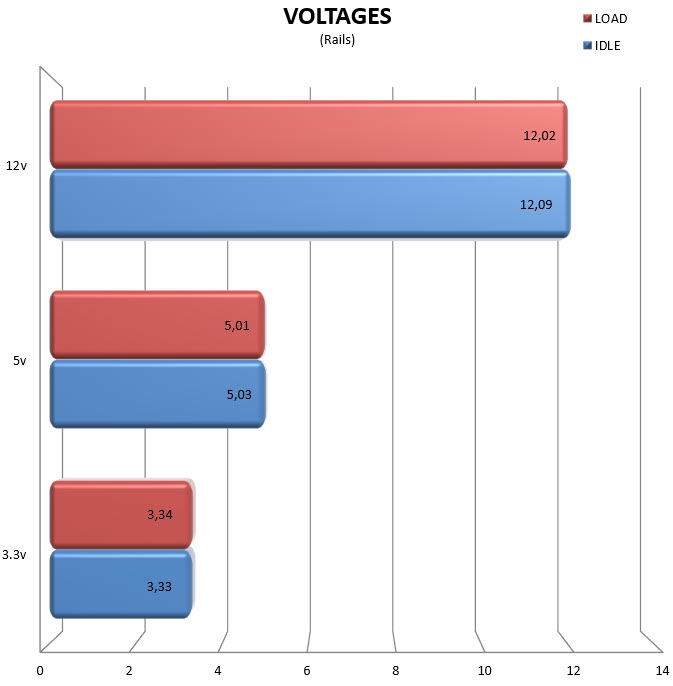

Rail stability was checked/measured with the CPUID Hardware monitor and a Metex multimeter which also recorded the system load in idle and in load. As always try to remember that the power consumption numbers listed in the graph are the highest (Peak) ones recorded during the entire duration of the tests and not the average ones. Noise levels coming from the fan were recorded using the high precision HD600 ExTech Sound dBA Meter from the rear of the unit and at a range of no more than 5-10cm. Readings under load are recorded the exact moment we manually switch the fans of all graphics cards from full speed to almost zero, that way the fan of the power supply does not have enough time to slow its RPM and so by doing this we get very accurate noise level readings. Needless to say, in order to get 100% accurate readings, you need to have a noise isolated room for that exact purpose, something which is quite impossible unless you are working inside a real lab (some people use very small noise insulated boxes but due to their size both heat and noise exceed normal levels and so the results can't really be considered to be 100% accurate, nor realistic for that matter). Also do take into account that since all noise measurements take place from just 5-10cm away the final noise levels to reach your ears will be considerably less.

* After well over 10 years of testing PSUs the Intel Core i7-920 CPU of this rig failed and so we replaced it with a Xeon X5660 (we also swapped the GA-X58A-UD7 for the G1. Assassin).

TEST RESULTS

CONCLUSION

The first Hydro PTM PRO 1200W PSU by FSP was one of the best to ever reach the lab and so the upgraded ATX 3.0 & PCIe 5.0 model couldn’t had been any worse, and it’s not. Rail stability is more or less identical, the 135mm fan produces slightly less noise at roughly the same load, build quality is excellent and as for the +12VHPWR connector it all but ensures you won’t be needing a new PSU for the foreseeable future. The 80 Plus Platinum electrical efficiency certification is of course always a great sign so there’s really nothing wrong with the Hydro PTM PRO 1200W ATX 3.0 model.

What about cost? Well currently the FSP Hydro PTM PRO 1200W ATX 3.0 PSU retails for just USD227.13 inside the USA (Amazon.com) and for 266.80Euros inside the EU (Amazon.de), a price tag which is rather tempting, especially on the other side of the Atlantic. Bottom line leaving out the output wattage (which for some people might be too much –the same unit is also available in 850/1000W outputs) the Hydro PTM PRO 1200W ATX 3.0 by FSP is an excellent PSU and for that it deserves the Platinum Award.

PROS

- Excellent Build Quality

- Solid Rail Stability

- ATX 3.0 & PCIe 5.0

- 80 Plus Titanium Certified

- 1200W Output

- +12VHPWR 600W Connector

- Single Powerful +12V Rail (100A)

- Fully Modular

- Electrical Protections (OCP/OVP/SSP/OPP/UVP/OTP/SIP)

- Noise Levels (ECO Fan Mode)

- 10 Year Limited Warranty

- Price (USA)

CONS

- None

O-Sense

O-Sense

.jpg)

.png)