INTRODUCTION

Even though both SLA (stereolithography) and FDM (fused deposition modelling) 3D printers have been around (at least in prototype form) since the 80's the latter has recently surpassed the former in terms of popularity primarily due to overall material durability. Still, there's no denying that SLA 3D printers offer higher model detail and better accuracy than FDM ones and so depending on the use such models could be the ideal choice, both for consumers and professionals alike. Anycubic is among the leading 3D printer manufacturers in the world and today with me i have one of their latest and most popular SLA 3D printers, the Photon Mono M5S.

As a well-known 3D printer R&D vendor and service provider, Anycubic has established sales, marketing and service system for clients all around the world, providing professional technology solutions and services, including 3D printing system operation services, rental of 3D printers, financing lease, sales promotion services, personal 3D printing consultation and also training services. With its advanced product portfolio and professional service, Anycubic satisfies the 3D printing requirements and improves user experience for its clients.

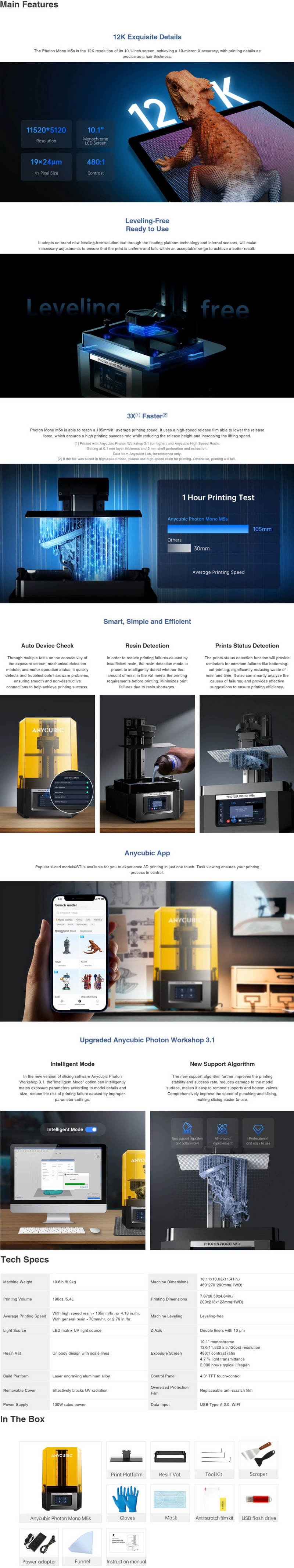

At first glance what sets apart the Photon Mono M5S compared to most of its competition is its achievable resolution of 12k (basically translates to 11520x5120 pixels with 19x24nm pixel size and 480:1 contrast), 105mm/hour average printing speed (with high speed resin), auto-bed leveling (via sensors and springs), 10.1" monochrome exposure screen (medium to large size) and its 4.3" touch display. The Photon Mono M5S also features a laser engraved metal build plate, sensors for both resin amount status and print status detection, large removable resin vat (850ml), USB 2.0 port and WiFi 2.4G connectivity. This is actually my very first time using an SLA 3D printer so let's see what you can expect from it in terms of print quality and of course speed (among other things).

SPECIFICATIONS AND FEATURES

PACKAGING AND CONTENTS

Anycubic ships the Photon Mono M5S inside a plain cardboard box that just has the made in China at the front along with details for their regional distributors.

Along with the Photon Mono M5S (main body and cover) and its power adapter inside the box you'll also find the resin vat with its 2 mounting thumbscrews, build plate, USB flash drive, two scrapers (metal for the build plate and plastic for the resin vat), 10.1" screen protector with cleaning accessories, disposable gloves, disposable masks, several paper funnels, 3 Allen keys, quality certificate and the user manual.

THE PHOTON MONO M5S

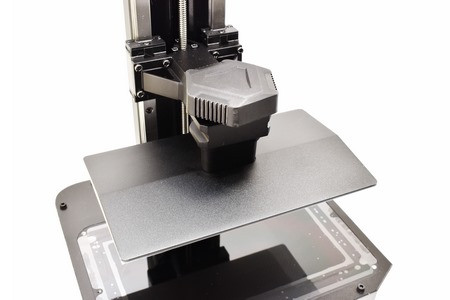

The main body of the Photon Mono M5S consists by the motorized Z-Axis and the 10.1" monochrome exposure screen.

In terms of height the Z-axis measures roughly 200mm top to bottom.

By default, the printing screen has a protective film which you'll need to replace with the screen protector prior to using the printer.

Typically, at the lower front we find the 4.3" touch display.

The printer specifications are placed on the left side whereas on the right side we find the USB 2.0 port.

The printer specifications are placed on the left side whereas on the right side we find the USB 2.0 port.

Turning the printer around we find the on/off power switch and the power port.

PRINTER ASSEMBLY

Even though the Photon Mono M5S comes almost 100% ready from the factory you still need to attach its parts (when all parts are mounted the printer weighs 8.9Kg and measures 460x270x290mm).

First you will need to attach the 10.1" screen protector and well even though the manual says you will need to remove all air from beneath there were several tiny areas which i couldn't do so (and yes, this could affect your model).

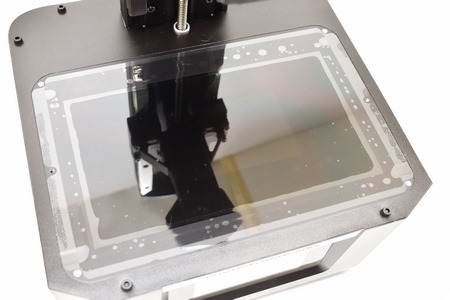

Then you will need to attach the build plate which is considerably larger from what I’ve seen with other SLA 3D printers (218.88x122.88x200mm build volume).

Last piece of the puzzle is the 850ml resin vat which gets secured in place with left/right thumbscrews.

Even though Anycubic send me both their Tough Resin Ultra and High Speed resins for my tests i decided to use the former due to better printing results (you can reduce printing times in half and even more with their high speed resin at the cost of printing quality).

TOUCH DISPLAY MENUS

After the Photon Mono M5S runs its auto device check the very first screen is the printing one from where you choose your model, either from the USB drive or local flash.

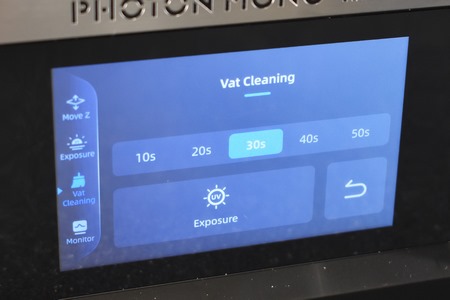

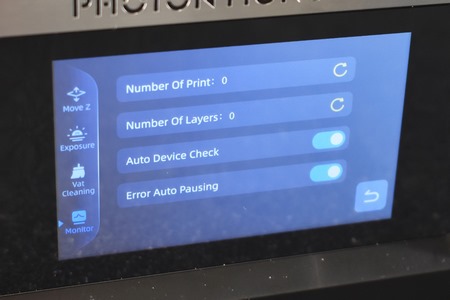

From inside the tools tab, you can adjust the Z-axis position (0.1/10/50mm increments), use the exposure function (10/20/30/40/50s), clean the resin VAT by enabling exposure (10/20/30/40/50s) and check the number of print jobs, layers and enable/disable auto device check and error auto pausing.

The info tab allows you to change the language, check the firmware version (prior to my tests i updated the firmware to version 1.0.4.0), enable/disable voice feedback and connect to your local WiFi and the Anycubic smartphone app.

Once you choose which model to print, you'll see a picture of it along with the completion time, required resin, layer thickness, total layers and speed (these all depend on the type of resin you'll use).

ANYCUBIC APP

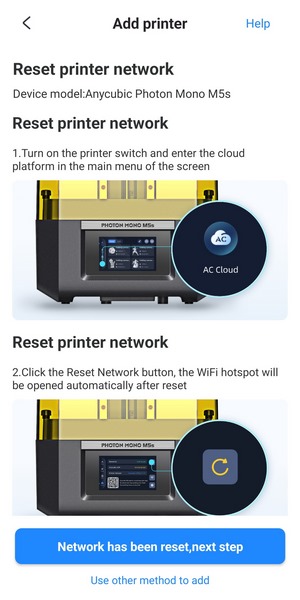

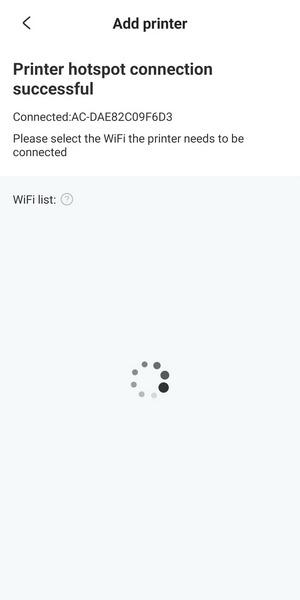

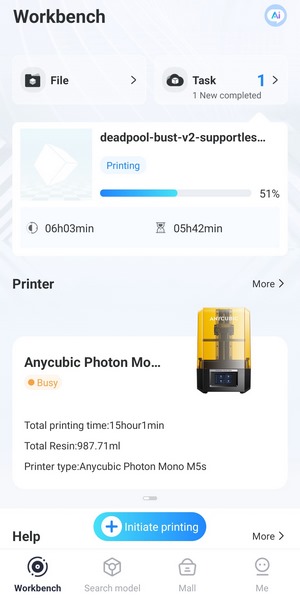

To gain remote access to your Photon Mono M5S you can download the Anycubic smartphone app.

After installation you will need to add a new printer and follow the on screen instructions.

Afterwards the main screen allows you to see the current state of the printer along with how many prints it has finished and how much resin it has used.

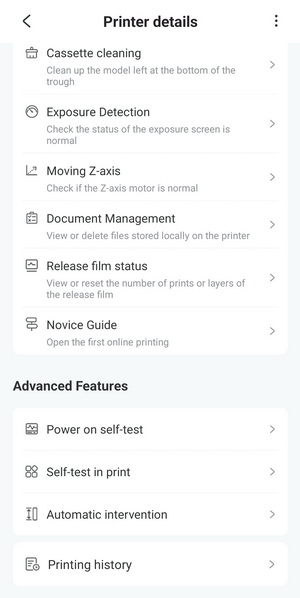

Inside the printer details you'll find everything available via the 4.3" touchscreen.

Of course, you can also rename the printer and perform a firmware update.

TESTING METHODOLOGY

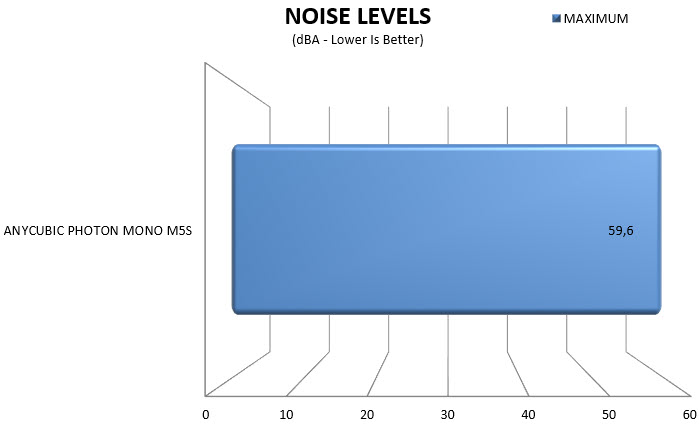

Although this might change later on for now i decided on using CHITUBOX when testing SLA 3D printers since it supports most models out there and comes recommended by most manufacturers. As for models I will be using 3 different ones, a small Star Trek model provided to me by a good friend of mine and the Deadpool Bust (downloaded from Cults3D / member Eastman) I’ve already been using with FDM 3D printers in two sizes, medium (86x68x122mm) and large (142x112x200mm) to record completion time at 100% speed (the large model might not be compatible with all SLA 3D printers to arrive in the lab in which case only the other 2 will be used). Second thing to test are noise levels and so once again I’ll be using my ExTech HD600 decibel meter placed roughly 30cm away to record the maximum noise coming from the 3D printer while printing. As for the 3rd test with the help of an UPS and two power meters I decided to also record not only the lowest and highest but also the average instant power consumption of the SLA 3D printer in my hands (separate charts with FDM models).

Here you can see two of the three models i printed with the Photon Mono M5S.

In a closeup you can see how the small model which i washed with isopropyl alcohol turned out and how the large one which i didn’t. Both models were cured out in the sun for 2-3 hours (since i don’t have a curing station here yet).

Even though i didn’t wash it with isopropyl alcohol you can still see the extra detail on the model compared to its FDM printed counterparts (it’s also a lot heavier).

TEST RESULTS

CONCLUSION

SLA 3D printers offer higher accuracy, detail and even watertightness to models and well, this is why professionals prefer them over FDM 3D printers. Now, having used and tested numerous FDM (fused deposition modelling) 3D printers already but still no SLA (stereolithography) ones i was quite excited to get my hands on the Photon Mono M5S model by Anycubic. It's quite large for most projects, very easy to setup and can be even equipped with its own air purifier (unfortunately Anycubic didn't send that along so I’ll probably test it in a future review - and yes, resin does smell). It's also fast (more on that in my next review), doesn't consume much electricity (nowhere near as much as FDM models) and as for quality everything checks out since it did produce more detailed models compared to FDM 3D printers (although not having used other similar models to date means that i don't know how it competes with them in this regard). Still i can't avoid pointing out three key areas where FDM models clearly have the upper hand, material cost, printer cleaning and model washing and curing. Resin bottles for example cost more compared to PLA filament and last less so even though SLA printers are in fact cheaper (at least when it comes to their FDM equals) and do consume less power you'll most likely have to spend more on material. What really stood out to me however in was cleaning, both of the tank and the build platform. You basically have two ways to clean them, one is to use isopropyl alcohol (extra cost) to break down the resin and then wipe it off and another is to use warm water and again wipe it off (takes far longer). On top of that liquid resin is not the safest substance out there so you need to year gloves and a mask whenever you use it. Model washing and curing also takes up time if you don’t own a wash and cure station so that too is something potential buyers need to take into account. Now i do realize that these may sound normal for people who have been using SLA 3D printers for a while but for a first timer such as myself post-print was somewhat overwhelming.

Currently the Photon Mono M5S 12K resin 3D printer by Anycubic retails for USD569.99 inside the USA (Amazon.com) and for 572.06Euros inside the EU (Amazon.de) so although higher compared to other SLA models it’s priced well, always for what it offers. Overall, I don’t really have anything bad to say about the Photon Mono M5S (post printing applies to all SLA models), quite the contrary since it did perform extremely well during the 2 weeks I ended up using it and since it delivers where it should it clearly deserves the Golden Award.

PROS

- Build Quality

- 12k Resolution

- Speed (Up To 105mm/h)

- Auto Leveling

- 10.1” Monochrome Exposure Screen

- Build Surface (218.88x122.88x200mm)

- Low Electrical Consumption

- 4.3” Touch Screen

- Anycubic App

- Bundle

CONS

- Post Printing (For Some)

- Price (For Some)

- Overall Material Durability

O-Sense

O-Sense

.jpg)

.png)